The REMod energy system model is a simulation-based optimization of (trans-)national energy supply systems which calculates possible cost-optimal transformation paths to a carbon neutral energy system. The optimization objective is to scale all generators, storage facilities, converters, and loads at minimum cost such that the overall system energy balance is met at every hour. Each technology property can be mapped in any level of detail.

| Model Type | Sector-coupled energy system model |

| Optimization approach | Simulation-based optimization |

| Optimization algorithm | CMA-ES |

| Temporal resolution (operation) | Hourly (8760 hours per year) |

| Temporal resolution (transformation path) | Yearly, today until 2045/2050 |

| Spatial resolution variable | currently 10 regions in Germany |

| Sector coupling | Combined optimization of the technology mix in the sectors industry, buildings, transport and energy |

| Flexibility and DSM | flexible operation and ramping behavior of thermal power plants, vehicle-to-grid and grid-to-vehicle, flexible operation of heating systems, no industrial DSM |

| GHG scope | energy-related CO2 emissions, restricted mitigation path and/or carbon budget |

| Weather data | Five historic weather data sets (currently 2011-2015) in alternating order |

| Foresight (transformation path) | Perfect foresight |

| Foresight (operation) | simulated 24h-forecast |

| Programming language | Julia |

Energy supply

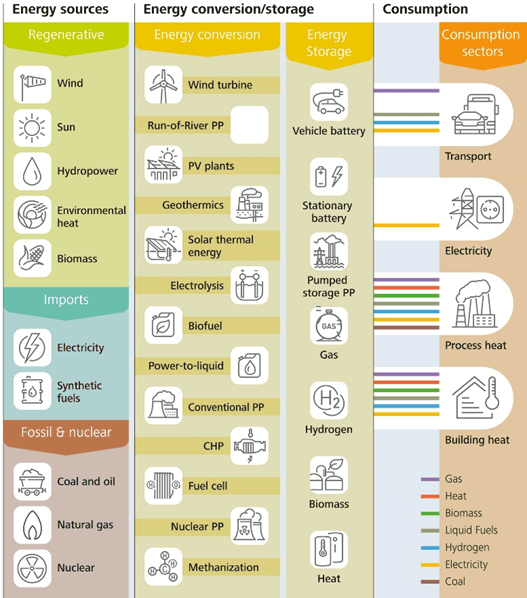

Figure 1 shows a schematic overview of the model, which illustrates the most important energy conversion technologies and consumption sectors. They are broken down into the main forms of (traditional) electricity applications (e.g. lighting, information and communication technology, refrigeration, mechanical energy), building heating (space heating, domestic hot water), transport and industrial process heat.

Energy demand

The final energy demand is divided into the four sectors: buildings heating (space and water heating), traditional electricity applications, industrial process heat and transport.

In REMod, the hourly demand for space heating and hot water in the buildings sector is calculated according to DIN EN 137901DEUTSCHES INSTITUT FÜR NORMUNG E.V.: Energieeffizienz von Gebäuden – Berechnung des Energiebedarfs für Heizung und Kühlung (ISO 3790:2008); Deutsche Fassung EN ISO 13790:2008. The input data used are the weather data from 2011 to 2015, buildings cubature, average living space or useful area per building type, number of buildings and age-dependent heat transfer coefficients. The values from the German industrial standard DIN EN 13790 are used for the energy efficiency and the calculation of the buildings energy demand. To supply the required heat, there are decentralized heating systems operating at two heating levels used, in addition to district heating technologies. The available heat supply technologies include conventional boilers based on methane, biomass, coal or oil, hydrogen boilers, engine-driven combined heat and power (CHP) units, electrical, fuel-based and hybrid heat pumps (with air or ground as heat source) and fuel cell systems based on hydrogen. All technologies can be optionally supplemented with hot water storage tanks and solar thermal collectors. In heating grids, heat can be supplied from geothermal or CHP plants, large electric heat pumps, (peak load) gas boilers or also solar thermal collectors. In addition, large thermal energy storage systems can be used in heat grids.

Energy used to provide process heat in industry is divided into two different temperature levels. For the temperature range below 500 °C an hourly demand profile close to the base load is assumed. For applications with a temperature higher than 500 °C, a constant energy demand is assumed. The total yearly energy demand for process heat is adjusted to FORECAST assumptions in Ariadne. For the supply of process heat, cost optimization in REMod can choose between nine different technologies, including conventional boilers based on fossil energy carriers or biomass, CHP units, hydrogen boilers, solar thermal collectors, industrial heat pumps and electrode boilers.

The energy demand for transport is first converted into traction energy (kinetic energy necessary for the movement of vehicles) on the basis of BMWi data and then distributed to each hour of the year using hourly resolved travel or demand profiles. The simulation model then determines the final energy demand for the respective fuels or electricity using the efficiency of the respective powertrain technologies. The energy demand for aviation and shipping as well as fuel-based railway traffic are also taken into account in the balance. The transport sector is represented in detail by passenger cars and trucks (only one class size each), which are each described by seven drivetrain concepts and the corresponding energy demand. In addition to the currently established combustion engines using gasoline, diesel or methane as fuel, battery-electric, hydrogen-electric (fuel cell) and hybrid powertrain concepts are implemented.

Flexibility is introduced to the energy system with battery storage, stationary and mobile batteries, thermal storage, and pump water storage. For example, different charging strategies for battery-electric vehicles or the interaction of thermal storage with different heating systems can be mapped realistically. Thus, in addition to ecological sustainability and economic efficiency, the model also takes into account security of supply through a high level of technical detail as well as a high temporal resolution. By incorporating real weather data, the influence of extreme weather years on the energy system is also considered. Similarly, a multi-node approach allows different regions (e.g., federal states) in the observation area to be mapped and their interaction with each other to be investigated, enabling conclusions to be drawn about infrastructure measures.

Policy instruments and measures

Implementing policy measures in REMod can be done in different ways. The cost of specific technologies can be adapted to implement monetary incentives and the CO2 price can be adapted. Specific expansion path goals can be implemented, as for example a specific goal for the transportation sector. Bans on certain technologies can also easily be implemented.

Methods and model framework

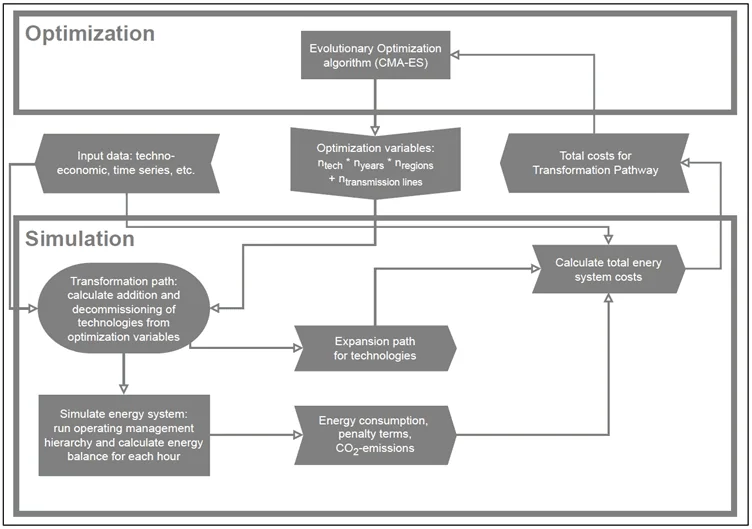

REMod uses a simulation-based optimization, where the cost-optimal transformation path (capacity additions in the energy sector and market shares in the end-use sectors) is optimized on an annual basis and the operation of the sector-coupled energy system is simulated on an hourly basis, as shown in Figure 2. The optimization algorithm (Covariance Matrix Adaptation Evolution Strategy (CMA-ES)) calculates the optimization parameters with the given input data (technology data, weather time series, etc.). The optimization results are now an input for the simulation of the transformation path. After the transformation path is calculated, the hourly simulation is run to match the energy balances for each hour. With the expansion path and the calculated energy consumption, the total system cost is calculated and given back to the optimization for a new calculation of the next population of possible solutions.

Links and references

- Luderer, G., Kost, C. and Sörgel, D. (eds), 2021. Deutschland auf dem Weg zur Klimaneutralität 2045 – Szenarien und Pfade im Modellvergleich (Ariadne-Report). Potsdam: Potsdam Institute for Climate Impact Research (Ariadne-Report). Available at: https://doi.org/10.48485/PIK.2021.006.

- Palzer, A., 2016. Sektorübergreifende Modellierung und Optimierung eines zukünftigen deutschen Energiesystems unter Berücksichtigung von Energieeffizienzmaßnahmen im Gebäudesektor. Stuttgart: Fraunhofer Verlag. Available at: https://doi.org/10.24406/publica-fhg-281042.

- Sterchele, P., 2019. Analysis of Technology Options to Balance Power Generation from Variable Renewable Energy Case Study for the German Energy System with the Sector Coupling Model REMod. Düren: Shaker Verlag GmbH. Available at: https://publica.fraunhofer.de/entities/publication/85d23ac1-ede7-490a-aa4f-9f240a891b2f/details.REMod-Studie

- Sterchele, P. et al. , 2020. Studie: Wege zu einem klimaneutralen Energiesystem – Die deutsche Energiewende im Kontext gesellschaftlicher Verhaltensweisen. Freiburg: Fraunhofer-Institut für Solare Energiesysteme ISE. Available at: https://www.ise.fraunhofer.de/de/veroeffentlichungen/studien/wege-zu-einem-klimaneutralen-energiesystem.html.

- Brandes, J. et al., 2021. Wege zu einem klimaneutralen Energiesystem: Die deutsche Energiewende im Kontext gesellschaftlicher Verhaltensweisen. Update November 2021: Klimaneutralität 2045. Freiburg: Fraunhofer-Institut für Solare Energiesysteme ISE. Available at: https://www.ise.fraunhofer.de/de/veroeffentlichungen/studien/wege-zu-einem-klimaneutralen-energiesystem.html.