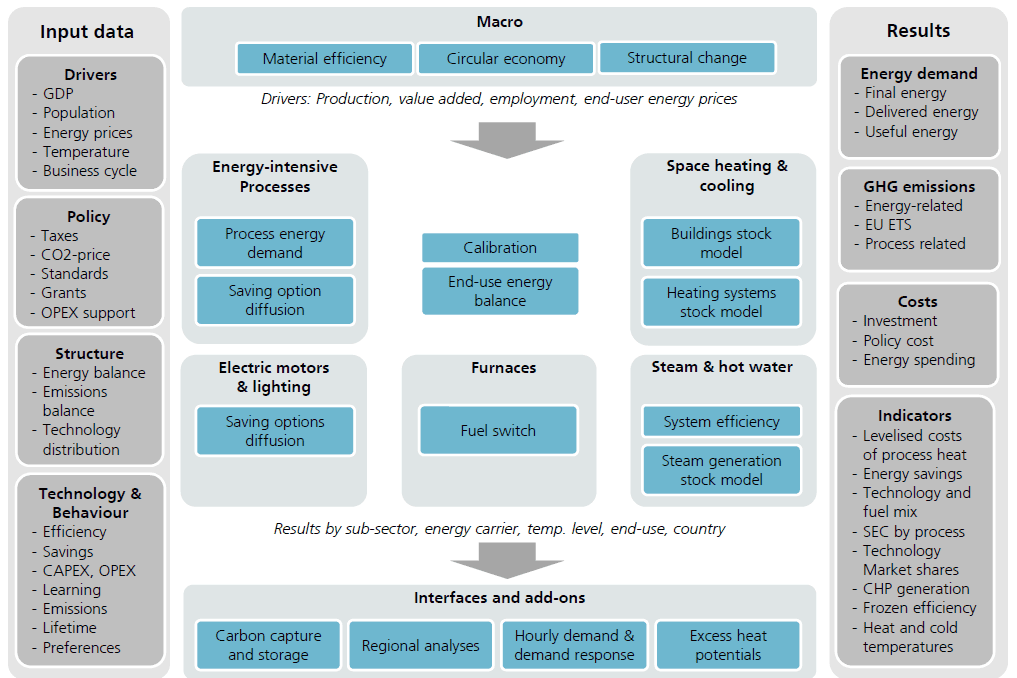

FORECAST Industry is a bottom-up simulation model. It calculates scenarios of energy demand and GHG-emissions of the industry sector. It is mainly applied to scenarios addressing climate change and industry transformation.

The main purpose of the FORECAST Industry model is to calculate scenarios of industry transformation with the background of climate change mitigation. It covers the European Union, UK, Switzerland and Norway and is usually applied within the timeframe of European and national climate targets (up to 2050). Main calculations happen on the national (NUTS0) level, with capabilities to disaggregate results downwards to NUTS3. The model includes industrial subsectors (e.g. iron and steel, cement, pulp & paper…) relevant to Eurostat1https://ec.europa.eu/eurostat/web/energy/database/additional-data#Energy%20balances and national energy balances (e.g. German AGEB2https://ag-energiebilanzen.de/daten-und-fakten/bilanzen-1990-bis-2030/), adding details on individual processes (e.g. blast furnace operation) and technologies (e.g. heat pumps, hydrogen-based direct reduction). Greenhouse gases (GHG) relevant to the industry sector are categorized as energy-related and process-related and include N2O, CO2, CH4 and fluorinated greenhouse gases – according to the National Inventory structure3https://unfccc.int/ghg-inventories-annex-i-parties/2023.

FORECAST Industry covers the EU27_2020, UK, Switzerland and Norway on a national level (NUTS0), with the option to disaggregate results down to small regions/districts (NUTS3). It excludes any form of international trade from endogenous calculations (has to be covered in scenario assumptions/definitions). The FORECAST model family also includes models for buildings and appliances.

Main drivers for FORECAST Industry are physical production amounts of energy-intensive basic materials. The respective production processes (e.g. steel production in the blast furnace route) are informed with statistical (past) data and assumed future developments, which are subject to scenario definition. In addition, gross value added of the manufacturing industry is used to reflect non-energy intensive industries. Important additional drivers for scenario development include energy carrier availability (e.g. biomass, hydrogen) and their prices, techno-economic data on specific production technologies, impacts of sufficiency and behavior change in other sectors (buildings, mobility) on basic material demand and carbon pricing. These drivers may interact and mix with policy instruments (see below).

FORECAST Industry considers about 80 industrial processes with individual properties regarding energy intensity, temperature profile of process heat demand, other energy use (e.g. fans, pumps), cooling and process-related emissions. In addition, 8 specific technologies for steam generation (dealt with as cross-cutting technology) and energy-carrier-specific sub-types are included. The industrial processes include energy efficiency potentials in a narrow sense, which are implemented according to endogenous calculation of payback-periods. The efficiency potential is thus considered to be conservative (as “automatic” efficiency improvements do not happen). Additional efficiency potentials (in a broader understanding) can be realized by diffusion of steam generation technologies (electric boiler, heat pumps) or process switches to new production technologies (e.g. from primary to secondary steel production).

The production of low- to medium-temperature process heat (hot water and steam) is tracked in a stock model, featuring explicit replacement of technologies according to lifetime (decision whether to replace installations) and total cost of ownership (decision with what to replace the installation). The technology choice is based on a discrete choice problem with logit formulation. Thus, available options are ranked by their utility value (how useful they are for the desired purpose, which includes their total costs). The highest-ranking option assumes the largest market share, with others following according to their rank. This structure allows for relevant price sensitivity and niche applications. This methodology to derive market shares is also applied to high-temperature heat but regarding energy carriers.

The bottom-up approach of FORECAST Industry is well suited for instrument-based analyses that investigate specific subsectors, energy carriers or technologies (e.g. EU-ETS, IPCEI, CCfDs, Ecodesign, circular economy actions). For example, it is used for ex-ante evaluation of the German policy mix as part of the documentation requirements of Regulation (EU) 2018/1999 of the European Parliament and of the Council of 11 December 2018 on the Governance of the Energy Union and Climate Action. In addition to instrument-based analyses, FORECAST Industry is often applied to exploratory scenarios and in combination with other sectoral- and energy-system models.

FORECAST Industry is a bottom-up simulation model. Therefore, the model uses highly-disaggregated data (“bottom”) on industrial processes (e.g. specific energy consumption of steel production) to explain observable high-level figures (“up”, e.g. electricity use in industry). The main approach is thus the assumption that the sum of all individual industrial activities constitutes the entire industry sector. Simulation means that the model strives to reproduce important aspects of decision-making (e.g. investment in new technologies) close to the actual process – including inefficiencies, lack of information and imperfect decisions.

FORECAST Industry is based on European or national energy balances (e.g. Eurostat, AGEB (Germany)). In addition, it uses techno-economic data from literature and production statistics to define properties of around 80 industrial processes (e.g. energy intensity, deployed and potential future technologies). The combination of these techno-economic data and scenario-based assumptions on industrial activity (physical production of specific products) yield energy demands per product, process and subsector. This energy demand can be influenced by energy efficiency, fuel switch (driven by fuel prices or regulations), technology replacement (e.g. electric boilers replacing natural gas-fired ones) or complete process switch (e.g. hydrogen-based direct reduction instead of blast furnace operations) – all of which may be impacted by policies included in the scenarios.

In this calculation process, additional information is added to the statistical data with which the model started – thus, the process is called “disaggregation of energy balances”. The disaggregated description of the industry sector is used to calculate possible futures in scenarios. In a final step, the model results are aggregated back towards the level of energy balances and calibrated to a given base year. The results thus represent a structurally compatible extension of the base statistic into the future along the scenarios defined in the project, with the main output of final energy demand, energy carrier shares and GHG-emissions by source (compatible with National Inventory Reports (NIR)).